Remain Ahead of Deterioration: Necessary Upkeep Tips for Undercarriage Parts

Wiki Article

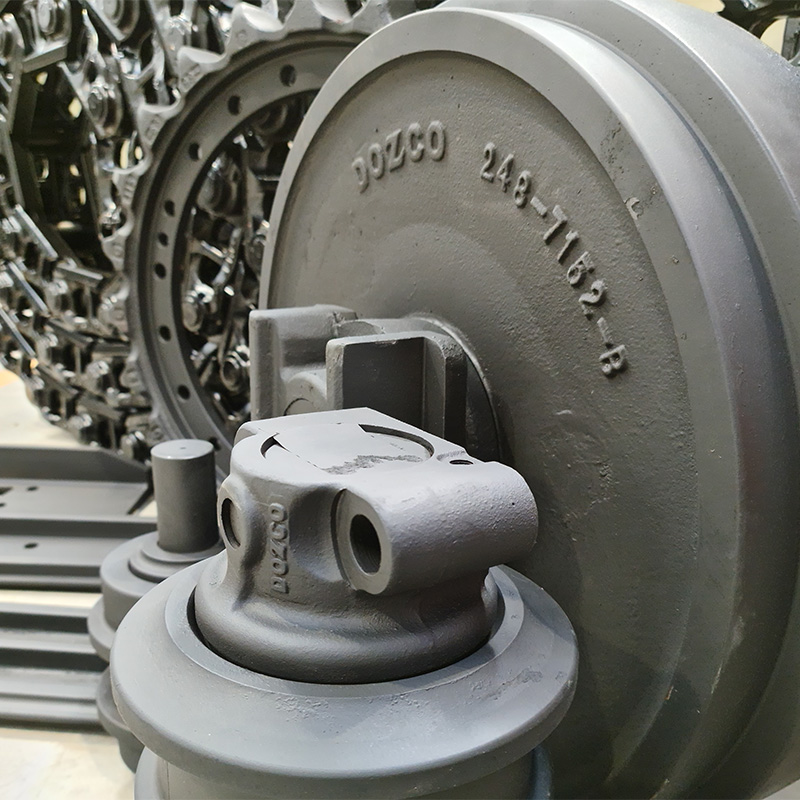

Maximize Performance With Sturdy Undercarriage Parts

In the world of heavy equipment and tools, the duty of undercarriage components is critical in ensuring optimal performance and longevity. The efficiency and performance of these parts can substantially influence the total procedure of machinery, making the choice of resilient undercarriage parts an essential choice for drivers and supervisors alike. By exploring the detailed partnership in between longevity and performance in undercarriage parts, a much deeper understanding of the subject emerges, clarifying the crucial aspects that drive operational success. As we navigate through the complexities of undercarriage longevity, maintenance, and element selection, a comprehensive exploration awaits to reveal the essential strategies for accomplishing peak performance in heavy-duty applications.Advantages of Utilizing Long Lasting Undercarriage Parts

Using durable undercarriage parts not only improves the durability of heavy equipment but also lessens maintenance expenses dramatically. By spending in top notch undercarriage elements, such as tracks, rollers, sprockets, and idlers, devices operators can experience raised uptime and improved general efficiency.

Additionally, the longevity of heavy equipment is directly linked to the top quality of its undercarriage parts. Long lasting components can hold up against the roughness of requiring applications, making sure that the tools stays operational for extended periods. Because of this, operators can avoid expensive downtime and upkeep expenditures, ultimately making the most of the roi for their machinery.

Variables Impacting Undercarriage Resilience

The longevity of undercarriage components in hefty equipment is affected by different important variables that directly impact performance and long life. Top notch products, such as hard steel, are necessary for enduring the extreme problems and hefty lots that undercarriage components are subjected to - undercarriage parts.Furthermore, ecological elements can have a significant effect on the durability of undercarriage components. Exposure to unpleasant products, extreme temperature levels, and severe working problems can increase deterioration on undercarriage elements. As a result, picking undercarriage parts that are particularly created to stand up to these ecological challenges is important for making sure durability.

In addition, the design and design of undercarriage components have a direct impact on their toughness. Parts that are developed to distribute tons equally, lower rubbing, and minimize tension concentrations are a lot more most likely to have a much longer life-span - undercarriage parts. By considering these important variables, equipment operators can make the most of the toughness and efficiency of their undercarriage parts

Maintenance Tips for Lengthening Undercarriage Life

Executing routine maintenance regimens is crucial for prolonging the life expectancy of undercarriage components in hefty machinery. In addition, make certain Extra resources that the undercarriage is appropriately lubricated according to manufacturer standards to decrease rubbing and stop premature wear.An additional crucial maintenance suggestion is to keep the undercarriage tidy from dust, rocks, and debris. Buildup in the undercarriage can speed up wear and rust, bring about pricey repairs. Washing the undercarriage after operation in harsh problems is advised to avoid these issues.

Finally, tracking and recording upkeep tasks can aid in creating an aggressive upkeep schedule. Maintaining comprehensive records of repair services, replacements, and examinations can offer valuable insights right into the undercarriage's condition and performance with time, aiding in forecasting and stopping prospective failures. By following these upkeep pointers carefully, operators can dramatically raise the longevity and performance of undercarriage components in heavy equipment.

Picking the Right Undercarriage Elements

Selecting proper undercarriage elements is critical for optimizing the efficiency and long life of hefty machinery. When it comes to choosing the ideal undercarriage parts, there are a number of variables to take into consideration.Choosing for trustworthy brands understood for creating durable and high-performance undercarriage parts can considerably affect the total efficiency and longevity of the machinery. By thoroughly selecting the appropriate undercarriage elements, devices owners can boost efficiency, reduce downtime, and extend the life expectancy of their heavy machinery.

Study: Boosted Efficiency With Sturdy Components

Including long lasting undercarriage components has demonstrated substantial enhancements in machinery efficiency. One instance research study included a building company that updated its excavator's undercarriage parts to more sturdy alternatives.In another instance, a mining procedure replaced the undercarriage components of its excavator with high-quality, durable choices. This switch resulted in an exceptional improvement in the excavator's maneuverability and overall efficiency. The equipment might browse difficult surfaces extra successfully, leading to improved operational efficiency and decreased gas intake.

Additionally, a logging company spent in durable undercarriage components for its forestry equipment. why not try here The upgraded elements displayed extended life expectancy and enhanced resistance to abrasion from harsh terrain. The company experienced minimized upkeep costs and better tools uptime, ultimately increasing its bottom line. These study emphasize the concrete advantages of using resilient undercarriage Learn More Here components in maximizing machinery performance and longevity.

Final Thought

In conclusion, using durable undercarriage components can significantly boost efficiency and longevity of heavy equipment. Situation studies have actually revealed that investing in long lasting undercarriage parts can lead to enhanced overall efficiency and efficiency in various sectors.The performance and performance of these components can considerably influence the overall procedure of machinery, making the selection of resilient undercarriage components a critical decision for drivers and supervisors alike.Integrating durable undercarriage components has actually demonstrated significant enhancements in machinery efficiency. These situation research studies emphasize the tangible advantages of using long lasting undercarriage components in enhancing machinery performance and durability.

In final thought, making use of sturdy undercarriage components can considerably boost efficiency and longevity of hefty equipment (undercarriage parts). Instance research studies have revealed that spending in resilient undercarriage components can lead to boosted overall performance and efficiency in different markets

Report this wiki page